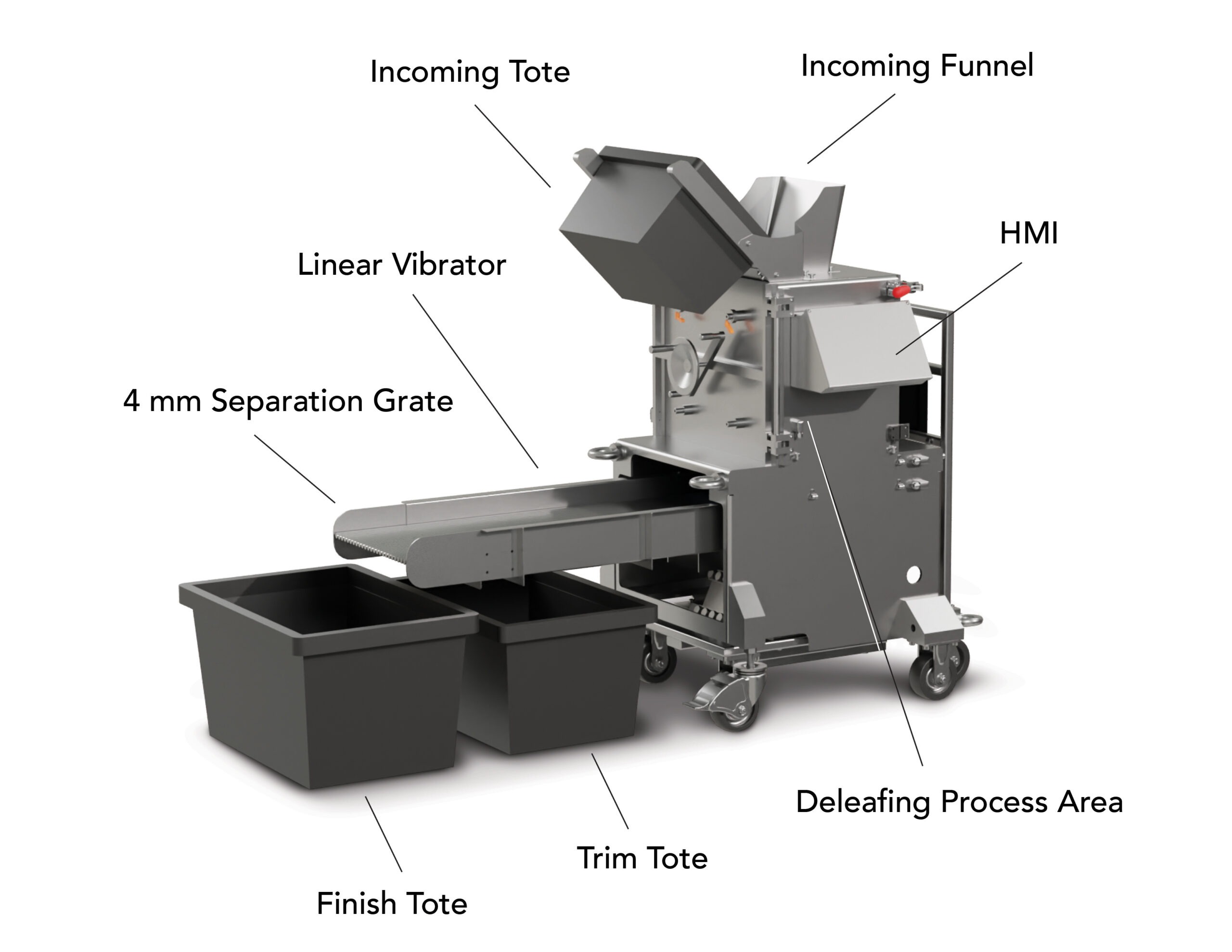

A Deleafing Cannabis Robot

We believe post-harvest processing is a manufacturing engineering task. Our indoor cannabis trimming machine is a game-changer. The trimming process has a direct correlation between grown flower yield and profit.

Why silicone?

• Increased flower yield for increased profit

• Natural flower formations are intact

• Preserve trichomes to reserve THC levels

and aromas

Robotic servo controls

• On-the-fly micro adjustments

• Store your settings

• 4-way process parameters

Indoor cannabis trimming machine basics:

Dimensions – 63”x31”x54”

Utilities – 120V 20 amps

Weight – 800 pounds

Dry flower output – 20 seconds/pound

Noise level – Normal conversation can be had

Placement of Softrim – In the dry room

Materials – Silcone, 304 stainless, hardened

aluminum, delrin

Safety sensors – Front door, back door, e-stop

Motors – Servo, direct, linear

Power cable – 20 foot

Warranty – 1 year

Design engineering – 10 year lifespan

Silicone finger belts – Lifespan approx 4K to 5K pounds